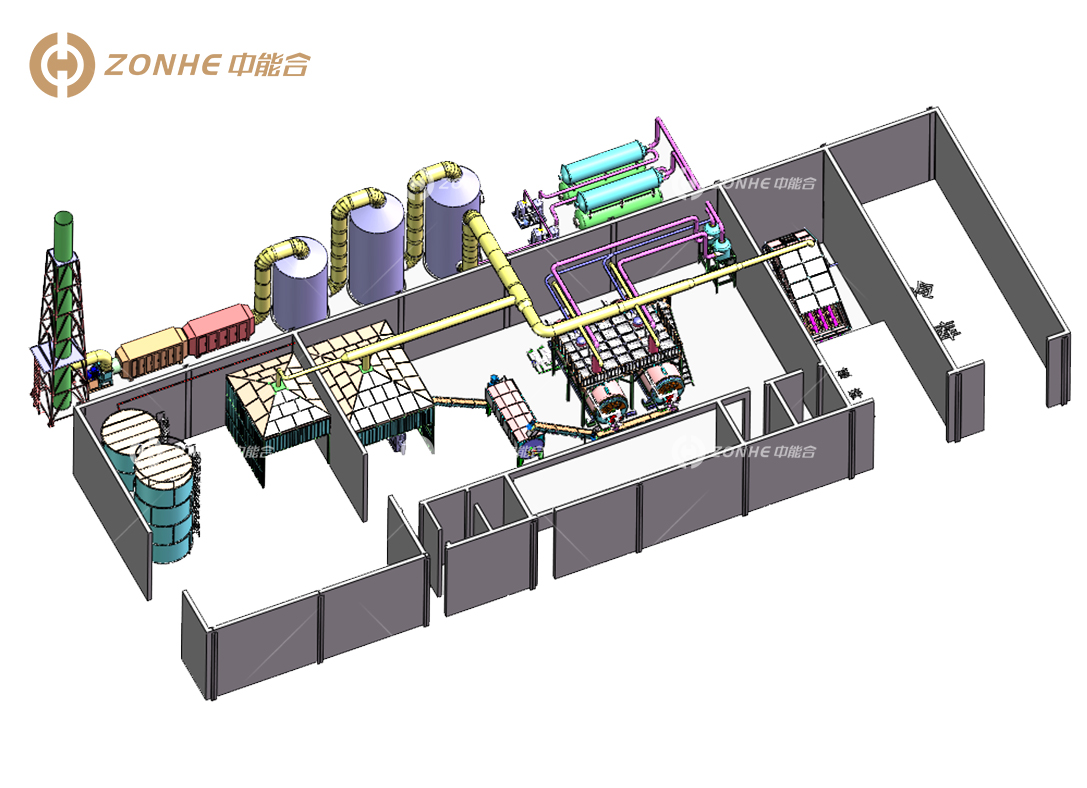

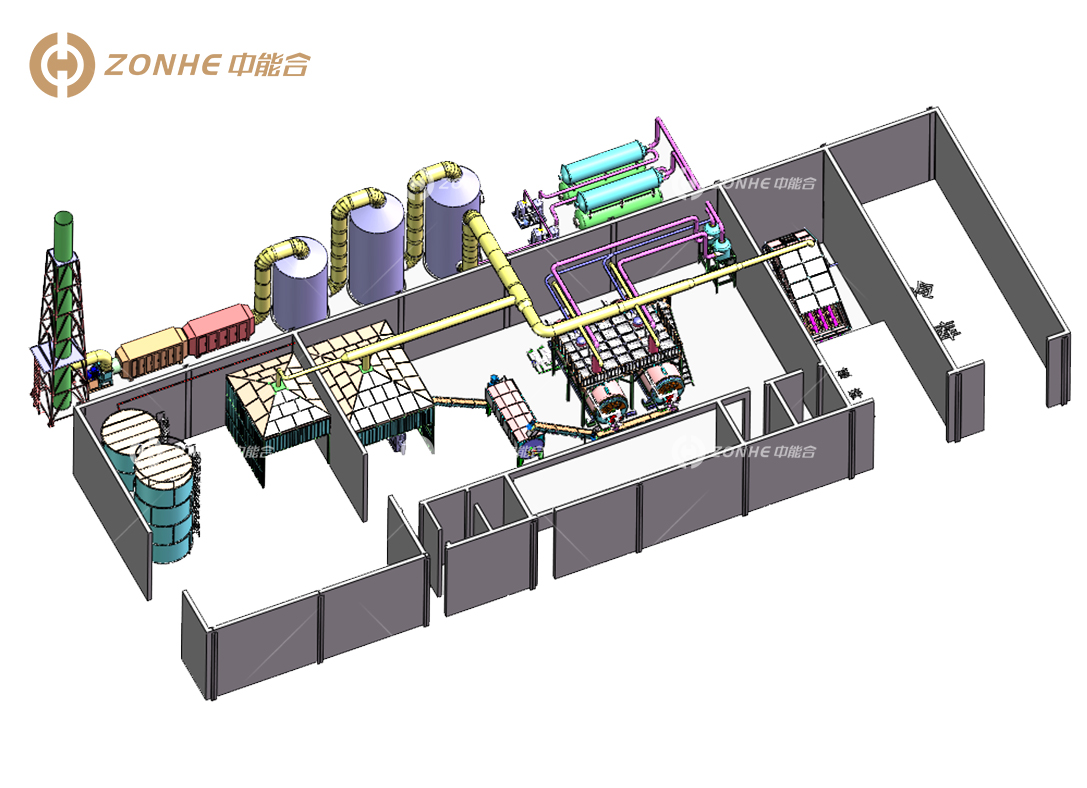

Slaughterhouse poultry waste rendering treatment process machine line

Poultry Waste Reception Section

This section includes a material silo designed for the reception and storage of poultry waste and deceased animals.

A pre-crushing machine is centrally located to process whole animal carcasses and large material pieces, reducing them to a target size of 50 mm for efficient transport.

At the base, a material pump is installed to facilitate the transfer of processed materials to the cooking unit.

Cook and Dry Section

Function: This section processes waste raw materials, including feathers, animal by-products, fur, sick livestock, and animal carcasses, utilizing high temperature and pressure to achieve effective sterilization and breakdown.

Features: It offers a high capacity for each batch, ensuring complete and safe sterilization efficiency. The system is capable of performing breaking, cooking, sterilization, and drying processes.

Cooling Section

The solid material from the cooker is conveyed to the cooling system via a screw conveyor equipped with a dust collection mechanism, where the temperature is effectively reduced to approximately ±5°C of room temperature.

Meal Section

Function: To reduce the particle size of the meal.

Features:

1. A specialized crushing chamber designed to enhance grinding efficiency.

2. An innovative rotor design and adjustable hammer-sieve gap, enabling the system to achieve various particle size specifications.

Packing Section

Automated packaging of the meal.

Odor Treatment Section

This section is designed to separate solids and liquids entrained in the vapor generated from cooking and drying equipment by utilizing a washing system for condensate collected from various process points.

Final Products

Tallow: Moisture content ≤ 1%

Meat and Bone Meal: Protein content ≥ 65%

The complete processing line comprises a material buffer bin, conveyor system, cooker-dryer, grinding unit, packing system, and odor treatment facility.

**Features**

- Automated control for rapid processing.

- Thorough cleaning to eliminate germs, utilizing environmentally friendly methods.

- Produces 100% odor-free output without generating secondary pollution.

- The processed end products contribute positively to social welfare and are widely recognized as effective treatment solutions globally.

** Function **

The treatment of waste materials (such as feathers, animal fur, diseased animals, and animal carcasses) is accomplished through high-temperature and high-pressure technology, ensuring effective sterilization.

** Characteristics **

- Large batch processing capacity.

- Safe and thorough sterilization effect, integrating crushing, sterilization, and drying processes seamlessly.

** Structure **

1. Jacketed design filled with steam for efficient heat transfer.

2. Inflatable stirring shaft to enhance heat exchange area and improve production efficiency.

3. Integrated steel structure bracket, allowing for flexible installation positioning.

4. User-friendly operation with a bump-type structure.

5. External insulation made of stainless steel to enhance corrosion resistance, extend service life, and provide an aesthetically pleasing appearance.

6. Utilizes a steam recovery system to recycle steam back to the boiler, reducing energy consumption and conserving water.

lmj@hhhyu.com

Service hotline

+86 13964770500