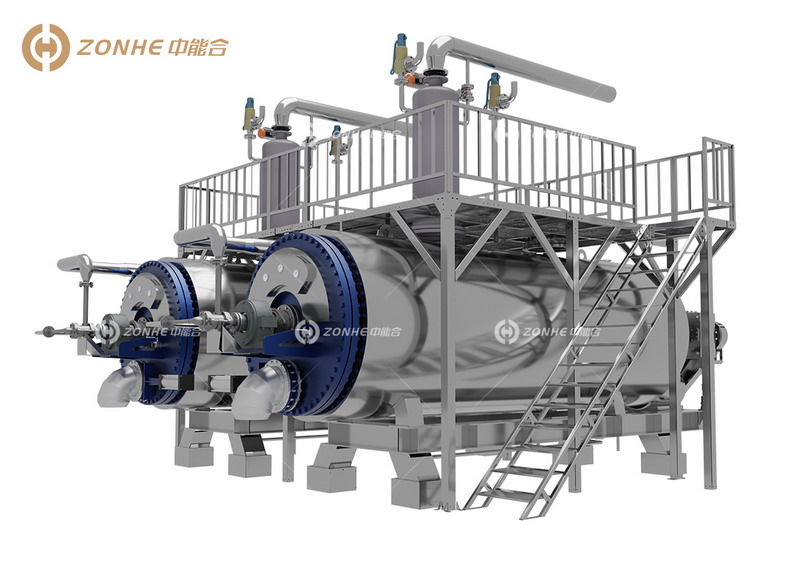

Slaughterhouse waste treatment equipment meat bone meal animal poultry feed production line

** Structure **

1. Jacketed design filled with steam for efficient heat transfer.

2. Inflatable stirring shaft to enhance heat exchange area and improve production efficiency.

3. Integrated steel structure bracket, allowing for flexible installation positioning.

4. User-friendly operation with a bump-type structure.

5. External insulation made of stainless steel to enhance corrosion resistance, extend service life, and provide an aesthetically pleasing appearance.

6. Utilizes a steam recovery system to recycle steam back to the boiler, reducing energy consumption and conserving water.

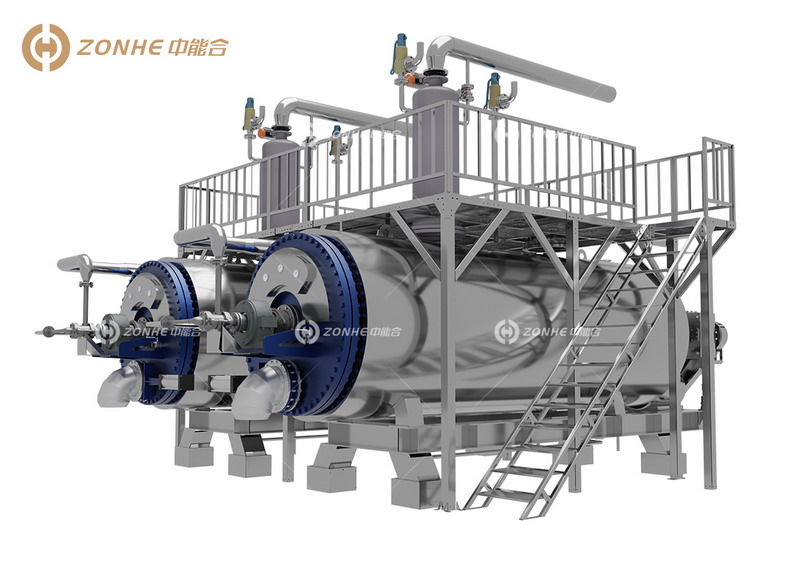

** Structure **

1. Jacketed design filled with steam for efficient heat transfer.

2. Inflatable stirring shaft to enhance heat exchange area and improve production efficiency.

3. Integrated steel structure bracket, allowing for flexible installation positioning.

4. User-friendly operation with a bump-type structure.

5. External insulation made of stainless steel to enhance corrosion resistance, extend service life, and provide an aesthetically pleasing appearance.

6. Utilizes a steam recovery system to recycle steam back to the boiler, reducing energy consumption and conserving water.

** Process Flow **

Crusher → Cooker → Dryer → Defatting → Cooling → Milling → Packing

After cleaning the feather dust, the material is placed into a hydrolysis tank where it undergoes hydrolysis at high temperature and pressure. The processed material is then dried, cooled, crushed, and packaged into finished products.

The hydrolyzed feather powder processing technology is relatively advanced, with the primary advantage of stabilizing the spatial structure of feather angle proteins. This transformation allows the proteins to become soluble and readily absorbable by livestock and poultry, achieving a digestion rate exceeding 75%. This product is suitable as a supplement in fishmeal, enhancing the overall sensory quality and flowability, while effectively reducing protein costs without compromising feeding efficacy.

** Notes: **

We offer customized turnkey production line solutions tailored to our customers' specific requirements. Our line includes a variety of machines, and customers can select the components that best suit their production needs and budget. Regardless of your requirements, we are committed to collaborating closely to meet your needs.

lmj@hhhyu.com

Service hotline

+86 13964770500